The Strongest Pistons in Powersports: JE Ultra Series

JE Pistons has taken their industry-leading forging technology and applied it to high-performance powersports engines that could use a little boost. Now available for popular UTV and sport bike applications, find out what JE Ultra Series Powersports is all about.

JE Pistons has built a leading reputation with custom pistons. It’s JE’s bread and butter, and top engine builders in the automotive and powersports industry rely on JE to make their design concepts reality. However, JE now offers shelf-stock pistons with new levels of strength and features normally reserved for the custom market, and they dubbed it the Ultra Series.

Developed through extensive experience designing pistons for countless types of engines and racing disciplines, the challenge first came in finding out specifically how to address needs across a broad group of automotive applications, and now that technology has been molded to serve powersports engines producing even the highest horsepower numbers.

Nickolaus DiBlasi, Director of Product Management for JE Pistons, explains, “We asked ourselves, ‘What are the most common parts we build that are really high performance that we are selling a lot of?’ We decided to make a nice category out of it, where we can provide the best features that are normally found on custom pistons, but instead as a catalog option. We grabbed the best applications and looked at the features that everyone normally wanted as a full race product. We built those into something that people could get off the shelf.”

“We grabbed the best applications and looked at the features that everyone normally wanted as a full race product. We built those into something that people could get off the shelf.”

The trend in the industry is that racers, builders, and enthusiasts are on a time crunch and need parts yesterday, which includes high-end premium pistons. That’s the idea behind the Ultra Series. It was natural that JE adapt Ultra Series technology to the powersports market after achieving sweeping success in the automotive category, beginning with both UTV and sport bike applications.

Modern day sport UTVs have made massive strides in performance, both in handling and horsepower, over the last decade, which has only opened the door for enthusiasts and racers alike to want to tap into their engine’s full potential, whether that be turning up the boost or maximizing naturally aspirated power. Either way, JE Pistons’ Ultra Series is ready to handle both, built to take abuse in these high-load, high-revving engines and come back for more every time. UTV applications JE Ultra Series pistons are available for include:

- Honda Talon 1000 models

- Kawasaki Teryx KRX 1000 models

- Polaris RZR 1000 XP and Turbo models

Complete Applications, Specs & Pricing Here

JE Ultra Series applications for sport bikes include the Ninja ZX-14 and Suzuki Hayabusa:

- 2006-2019 Kawasaki Ninja ZX-14

- 1999-2019 Suzuki GSX1300 Hayabusa

Both of these applications are offered in a variety of bore size and compression ratio combinations.

Get Complete Piston Specs and Pricing Here

JE Ultra Series sport bike applications are available for Suzuki Hayabusa and Kawasaki Ninja ZX-14 application, each of them available in various bore sizes and compression ratios.

The Ultra Series pistons are loaded with features that fall in the realm of custom, but are available off the shelf. Those features are highlighted below.

Aligned Grain Flow Technology

A piston undergoes a tremendous amount of stress during operation. That’s why material strength is so important. Because JE forges all their pistons in-house in the USA, they were able to develop a proprietary forging process that allows them to better direct material grain flow for increased tensile strength.

DiBlasi explains, “What’s massively different between the Ultra forging and any other forging in our line, or any other piston company on the planet for that matter, is that we have a proprietary process that enables us to fixture the part and hammer it in a certain way to align an additional 20% of the grains completely in-line with the piston’s specific shape.”

JE forges all their pistons in-house in the USA, allowing the opportunity to develop a proprietary forging process aligning the grain flow of the alloy approximately 20% better than a standard forged part translating to increased tensile strength and the ability to handle bigger power.

Typically, when an aluminum puck is forged, a majority of the material gets formed into shape. However, because the aluminum makes different turns and pushes itself into a cavity, not all the material gets pushed in the right direction. Since JE controls the process from getting the aluminum bar to the finished product, they were able to develop a specific forging process that allows them to pre-form the aluminum bars and pucks, better aligning the grain flow in one specific direction before the final piston shape is even formed. In final forging, all the alloy’s grains line up much more uniform in comparison to a part forged with the standard process.

JE’s Aligned Grain Flow Technology equips the Ultra Series line with approximately 20% more tensile strength, allowing them to not only withstand high-HP and big power adder applications, but to remain well within useful performance spec over an extended life. To put things in perspective, this strength standard is typically found in aircraft and high-end military components where the part needs to be as light and strong as possible.

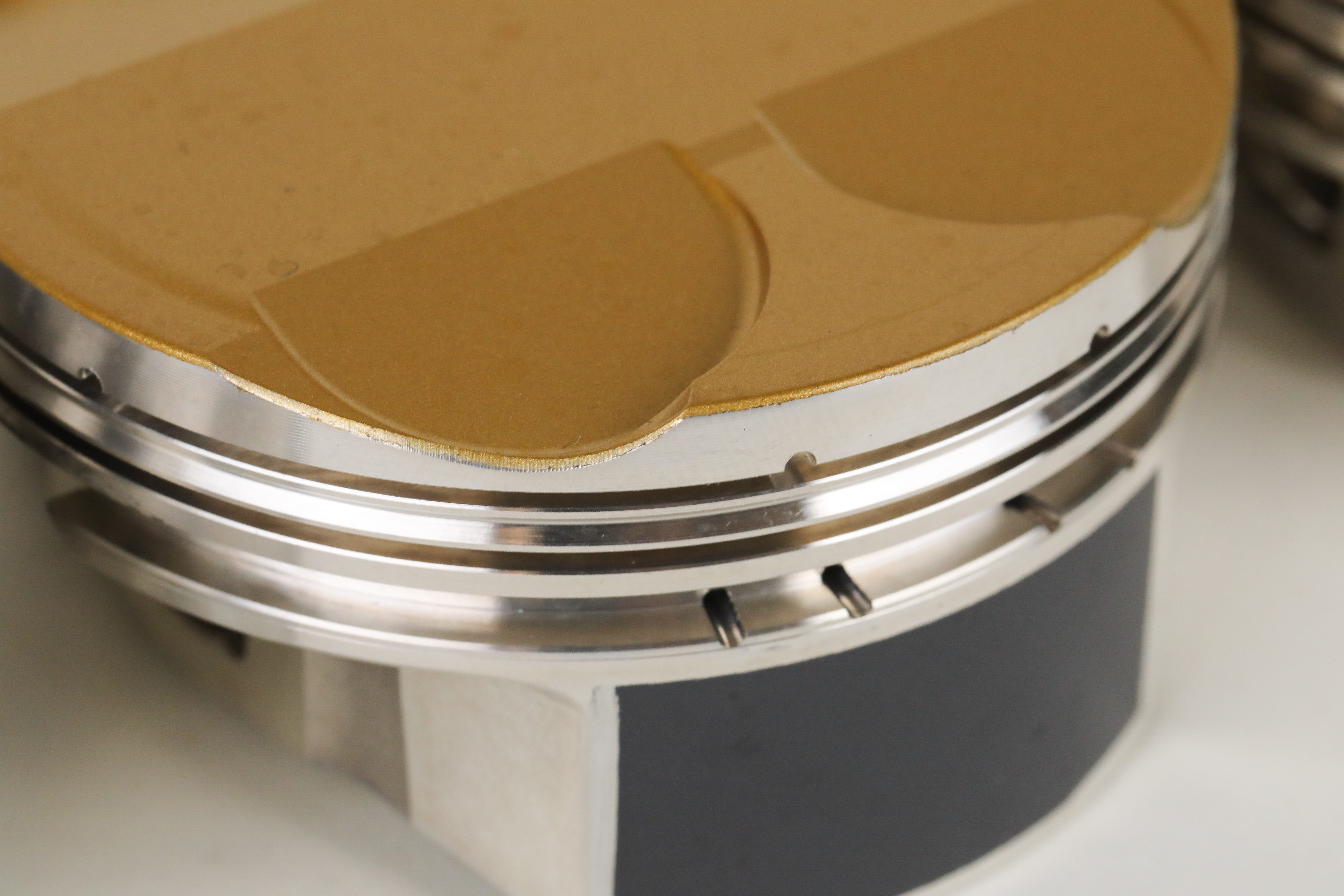

In the non-machined areas of powersports Ultra Series pistons, the improved grain flow of the aluminum is even visible to the naked eye in certain countours of the piston.

Accumulator Groove

Ultra Series’ added forging strength is just a base for the additional performance features JE designed into this high-performance piston line. An accumulator groove is machined into the ring land below the compression ring to create volume between the first and second ring. In most cases there’s a little bit of combustion gas that will get past the first ring during normal operation. Without an accumulator groove cut into that ring land, it will create a higher-pressure area between the first and second rings.

“We machine a sort of divot, or void, all of the way around that second land,” explains DiBlasi. “It increases the total volume, which reduces pressure for gas that gets trapped between the first and second ring. This allows the ring to seat better. Typically, you gap your second ring looser than your top ring. After a few cycles it will push past the oil ring and is unaffected. It gives you the strongest ring seal possible.”

The benefit of an accumulator groove is substantial. There is a gain of 8-10 horsepower on an automotive application, and horsepower gains will certainly translate over to something like a four-cylinder Hayabusa engine.

Lateral Gas Ports

All Ultra Series pistons across the board come machined with lateral gas ports, which are small passages drilled through the top ring land, channeling into the back of the top ring groove. As the combustion occurs, it pushes the gases through the channel and into the back of the top ring, which forces the ring out to the cylinder wall. Not only do you have the accumulator groove assisting in stability of the compression ring, but lateral gas ports help maintain strong and consistent ring seal.

Lateral gas ports allow combustion gases to get behind the compression ring, aiding greatly in consistent ring seal which is crucial for performance, especially in high-power, boosted applications.

DiBlasi elaborates, “Thanks to lateral gas ports you get a very secure ring to the bottom of the ring groove, and a very secure ring to the cylinder wall. That way the piston holds as much combustion as possible. There are gapless rings out there, and their purpose is to get as much feeling as possible. Gas ports are a way to get combustion to do the same thing. It’s highly successful.”

Engine aficionados know that there are different types of gas ports. Drag race builders rely on vertical gas ports for their engines. JE uses lateral gas ports because they want your engine to live longer and not have any of the ports get clogged, leading to piston ring failure. Regardless of port design, understand that there’s a notable performance gain in sealing alone due to using gas ports.

Dual Pin Oiling

A lot of OEM/factory applications have single pin oiling. JE opted for dual feeds to improve lubrication to the wrist pin, thus helping to extend piston, and connecting rod small-end life. Based on the application, JE relies on forced pin oiling or dual broaches. Essentially, it’s two different ways to get oil to the wrist pin.

Depending on the application, Ultra Series powersports feature forced pin oilers (channels through the pin boss into the pin bore), or double broaches (seen here), which are channels cut parallel in the pin bore, feeding oil to maintain a consistent film around the wrist pin. High-RPM, high-HP engines can generate a lot of heat in the wrist pin areas and sufficient lubrication is crucial to preventing premature wear or damage.

In addition, every single Ultra Series piston comes with an upgraded 180-wall, 9310 steel wrist pin, which has a heavy-duty wall thickness, extremely important for maintaining proper operation in high-power engines.

Thermal Barrier Crown Coating

Heat is a major reason for decreasing a piston’s lifespan. JE has developed a proprietary ceramic gold crown coating that is applied in-house and rejects a large portion of the damage-causing heat piston crowns are subject to.

DiBlasi adds, “Typically, a piston gets annealed, or softens, over time due to heat cycling. The crown of the piston pulls a lot of heat into it. At some point there is a life cycle to aluminum. The softer the piston gets, the more it will take on an umbrella shape. Then comes end of life. Some engines don’t make enough power and the piston will out-live the engine. In something like a Top Fuel dragster, you can get a couple passes out of the piston and then it’s junk. We apply a ceramic crown coating in our signature gold, which reflects heat into the chamber as much as possible, pushing it out the exhaust side.”

When all things are operating properly in the engine, the ceramic gold coating gives the crown virtually an unlimited lifespan without any issue of the piston annealing. Case in point, on a Hayabusa you could theoretically make 1,200-horsepower with a JE Ultra Series piston and it won’t have a problem handling that amount of stress. Please let us know if you build a 1,200-horsepower Hayabusa, we want to see it.

Skirt Coating

The most variable component of the Ultra Series line is the coating that is applied to the piston skirts. JE has several different types of specifically formulated skirt coatings depending on what the factory block is made of concerning expansion and piston-to-wall clearance. For example, JE uses a different skirt coating on their Hayabusa and Ninja ZX-14 than they do on a Honda turbo application for automotive. The Honda is usually a steel sleeve on an aluminum block. JE has a Porsche application designed for an air-cooled aluminum sleeve on an aluminum Nikasil coated block. Each one is compatible for what the factory and aftermarket configurations are. Many of them have a skirt coating, but the chemical makeup and thickness are different in order to live in the environment they are designed for.

“Our Ultra Series powersports pistons have a screen-printed, moly-based dry film lubricant that is 14 microns thick,” explains DiBlasi. “Powersports operate at such small clearances that our thinner coating proves to be most beneficial for longevity and performance.”

The skirt coating is designed to protect the piston skirts, reduce friction and overall wear, and eliminate cold-start piston slap.

Ease of Ordering: Pistons and Components Included

Ultra Series powersports pistons are supplied in kits complete with ring pack, wrist pin, and wire locks, all under one part number. This eliminates the headache of ordering individual items and part numbers just for a piston install.

JE Ultra Series Powersports Current Applications

JE has now launched the Ultra Series for popular UTV applications as well as sport bikes, including Polaris RZR, Honda Talon, Kawasaki KRX, Kawasaki ZX-14, and Suzuki Hayabusa. Those applications require an extra strength piston since they typically see forced induction in high-performance and racing builds, and must meet the demands of increased heat and cylinder pressures. JE will soon be rolling their Ultra Series line into more off and on-road powersports applications as well.

Thanks to the many features of Ultra Series line, racers have a custom piston available off the shelf. They also have one less part to worry about. Engine failure is minimized due to the tech advancements, and performance gains are massive. In the high-risk, high-reward world of racing, the Ultra Series is a home run.