Ring Installation Guide 4032 Pistons Instructions

BEFORE BALANCING, installing pins, rods, or locks, please check the part number and description on box label to be sure you have the correct components. Shelf pistons that are altered, scratched or damaged are not returnable. Custom Pistons are returnable only for manufacturing defects.

Piston to Cylinder Wall Clearance

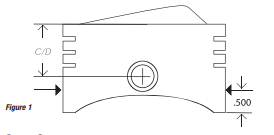

- Piston diameter must be measured at gauge point which, in most cases, is .500″ up from the bottom of skirt. (See fig. 1). Dimensions listed are gauged at a temperature of 68 degrees fahrenheit. Note: aluminum expands and contracts with temperature variations.

- Your pistons are manufactured from 4032 high silicon aluminum alloy.

- Clearance is built into piston based upon finished bore for normal operating conditions. (See Table. 1).

- Clearances listed below are minimum. Some applications such as supercharged, turbo, nitrous and endurance applications may require .001″-. 003″ to be added to the minimum clearances in Table 1. Cold water pickup marine applications may require an additional .002″-.004″ clearance.

| Table 1 | Bore Range | Min. Clearance |

| Sport Compact | 2.500 to 3.625″ | .0020 to .0025″ |

| Sport Compact | 3.626 to 3.999″ | .0025 to .0030″ |

| SB Applications | 4.000 to 4.200″ | .0020 to .0025″ |

| BB Applications | 4.200 to 4.600″ | .0030 to .0035″ |

Piston to Valve Clearance

Piston to valve clearance is determined by cam lift, lobe separation, duration, valve margin, head design, and aftermarket milling of cylinder head. Minimum recommended clearance for intake & exhaust valve would be 0.100″ deep and .050″ radially. Check by using clay or follow cam manufacturers recommendations for checking clearance, making sure the cam is degreed exactly as it will be during operation.

Cylinder/Liner/Block Preparation

We strongly recommend that you chamfer or slightly relieve the bottom edges of your cylinders/liners/blocks. If a sharp edge is present it will cause excessive piston skirt wear. This is very important in stroker applications where the piston skirt travels past the bottom of the cylinder.

Piston/dome to head and spark plug clearance

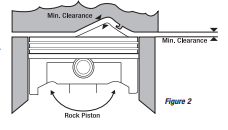

Due to the large selection of aftermarket cylinder heads available, and wide variety of combustion chambers, you should always check piston/dome to head and spark plug clearance to assure proper clearance (See fig.2). Minimum clearance for steel rod =.040″, aluminum =.060″. Check using clay with piston installed on rod at TDC, rock piston to get minimum clearance.

Crank Counterweight to Piston Clearance

Always check counterweight to piston clearance ar BDC. Recommended minimum is .060″.

Connecting Rod to Piston Clearance

Due to the large variation in rod widths and material thickness above pin, always check for proper piston to connecting rod pin end clearance. Recommended clearance is .050″ min per side and .050″ min from top of rod to piston. With the piston installed on the rod, rock the piston side to side and rotate forward and backward to ensure proper clearance. (fig. 3)

Spiro Locks

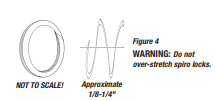

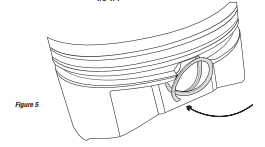

For installing Spiro locks, grip each end of the lock and pull apart (approx. 3/8” – 7/16”).The lock will resemble a small coil (fig.4).The lock can then be spiraled into place almost as if you were screwing them into a groove (fig. 5). When the locks are properly seated, only half of the lock will be visible above the groove. Most SRP pistons that require spiral locks will need 4 locks per piston, 2 at each end of the pin. WARNING: It is important that the correct number of locks are installed in each piston or severe engine damage may occur. WARNING: Do not over stretch spiro locks and do not reuse spiro locks!

Wire Locks

Install the end of one lock at 90 degrees from the pick lock groove. Use a stiff small bladed screwdriver and insert the tip into the pick lock groove while you wedge the lock into the groove without kinking or deforming the lock. After the first lock is in place, seat the lock by solidly hitting the wrist pin with a brass drift pin. Now install the connecting rod and the second lock. Seat the 2nd lock in the same manner as the first. Just as a precaution, we recommend hitting each side of the wrist pin with the brass drift pin an additional time. Perform these functions on a cloth towel or soft rubber pad so no damage to the piston occurs.

Cleaning

Thoroughly scrub pistons and cylinder walls with an automotive parts type cleaning solvent or hot water and soap before installation. JE recommends a light coat of assembly oil (Marvel Mystery Oil or similar) on the pistons’ skirt, rings and cylinder walls for initial installation and start up. WE DO NOT RECOMMEND USING SYNTHETIC OIL OR ANY AFTERMARKET OIL ADDITIVES until the rings have properly seated. Be sure to thoroughly lubricate wrist pins and piston pin bores with an assembly oil to prevent galling on initial fire-up. It is also a very good idea to double check forced piston pin oiler holes for foreign matter or debris before ring installation. During trial assembly or mock-up, verify the dome and valve pockets on the pistons match the combustion chamber and valve diameters of your cylinder heads. As a rule, four-valve piston exhaust pockets are located above the JE logo on the underside of the piston. Many JE/SRP piston designs have special offset domes and /or specific valve pocket “left” or “right” hand positions. It is the responsibility of the engine builder to ensure non-symmetrical (left or right designed pistons) valve pocket pistons are installed in the correct cylinder location.

Ring Installation Guidelines

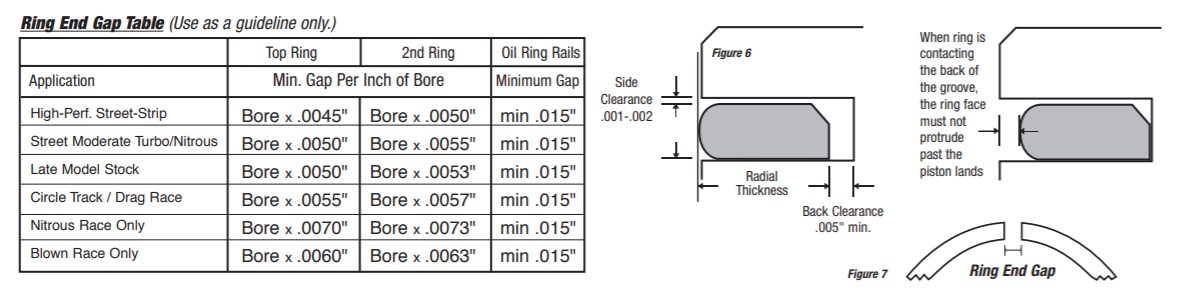

IMPORTANT: BEFORE FILING RINGS – Check each individual ring in its corresponding piston ring groove to ensure proper ring groove depth (radial back clearance) and side clearance (thickness)(fig. 6). Proper cylinder finish (honing), ring end-gap, and lubrication are critical to achieving optimum ring seal.

End Gap

End gap is the clearance between the two ends of a piston ring as it is installed in a cylinder (fig. 7). Most high performance and racing engine builders purchase piston rings slightly oversized in order to file fit them to very precise end gaps. Testing has shown measurable increases in horsepower and decreases in blow-by as a result of properly fitting the ring end gap to the operating conditions. Factors such as supercharging, turbocharging, nitrous oxide, endurance racing and different fuels determine proper ring end gap. Proper ring end gap can more than double from one engine to the next depending upon the above factors.

Precise machining of the cylinder bores is critical, and is the reason why rings should be fitted to the cylinder in which they are to be installed. A diameter variance from one cylinder to the next changes the end gap of the rings in that cylinder by a factor of pi (3.1416). For example, a cylinder .001” larger in diameter will increase the ring end gap by .001 x 3.1416 = .003”, rounding off. The second ring end gap should always be larger than the top ring end gap.

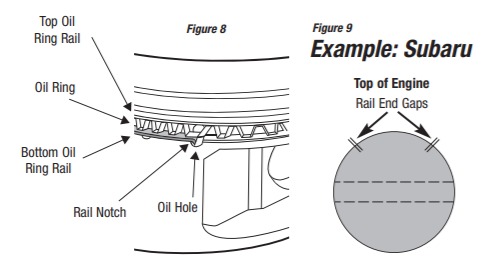

Rings Sets Containing Rail with a Tab

When installed in a horizontally opposed engine, oil rail gaps should be installed as shown at below (fig. 9). The tab rail must be installed below the oil ring expander with the tab facing toward the bottom of the ring groove extending into the split oil drain back holes (fig. 8). Use caution not to install the rail tab into the wrist pin oil hole.

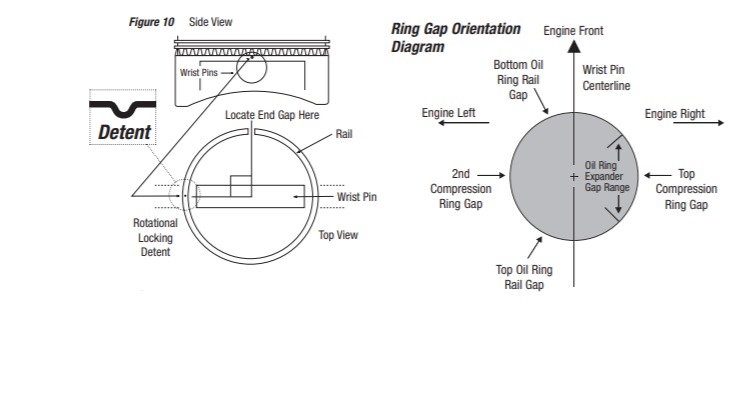

Oil Ring Support Rail Installation

- Install oil ring support rails on the bottom of the oil ring groove with the antirotational locking detent facing downward.

- Rotate the oil ring support rail until antirotational locking detent falls between the opening at intersection of ring groove and wrist pin hole. (fig. 10)

- Install oil ring assembly as usual.

THESE GUIDELINES CAN ASSIST IN THE INSTALLATION PROCESS TO HELP ENSURE CORRECT OPERATION AND MAXIMUM PERFORMANCE BUT ARE NOT INTENDED AS COMPLETE INSTALLATION INSTRUCTIONS.