Piston Ring Upgrade: DLC-Coated SP3 Rings from Pro Seal

Delivering leading longevity and wear resistance alongside consistent, power-promoting ring seal, Pro Seal’s latest piston ring innovation is the ultimate complement to any performance build.

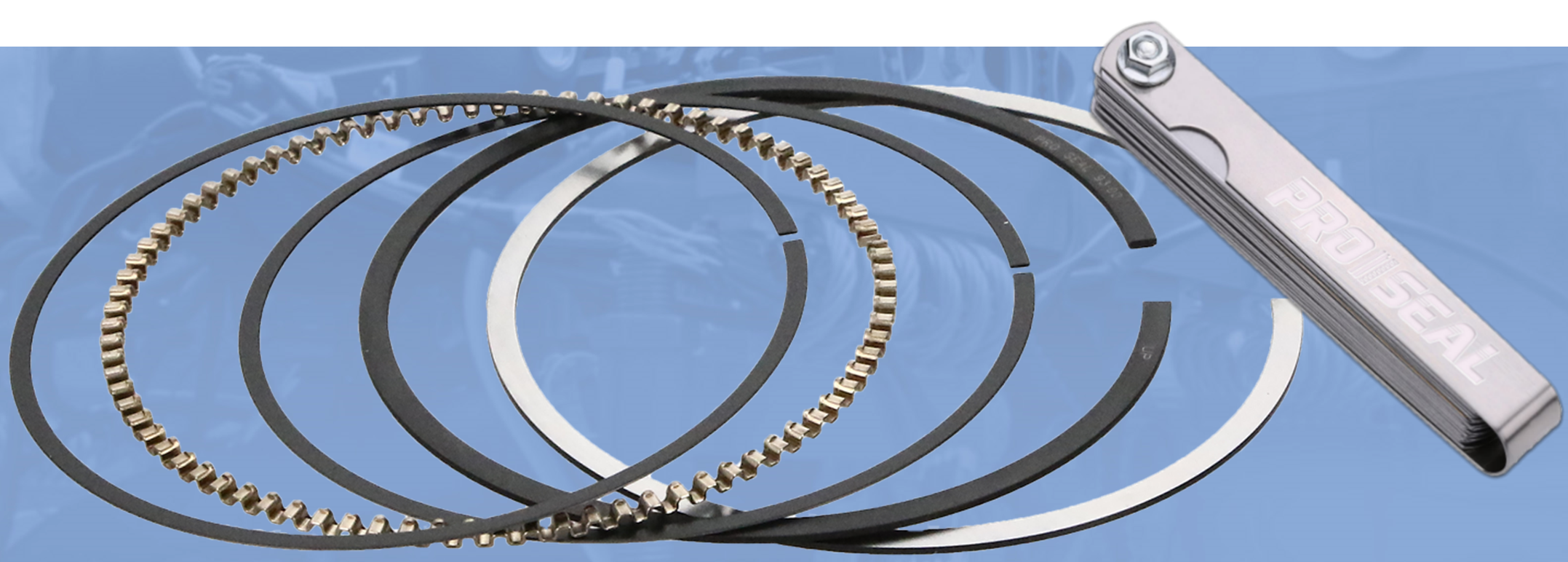

Designed to promote industry-leading longevity and wear resistance while delivering consistent, power-promoting ring seal, Pro Seal’s latest piston ring innovation can serve your precision, high-horsepower build from classic to modern. SP3 ring packages consist of a DLC-coated, carbon steel top compression ring, Napier carbon steel second ring, and DLC-coated oil rings.

How do SP3 rings deliver on their horsepower promise?

Top Compression Ring – 1.0mm

- Carbon steel construction provides optimal strength characteristics while promoting lower chances for ring micro welding and tension loss, contributing to longer, more consistent sealing performance.

- A standard in high-performance, DLC coating on the top ring provides a significantly lower coefficient of friction during engine operation, contributing to less parasitic load and higher power translation. This also allows for the use of thinner oils and provides compatibility with DI engines and dry sump systems. Increased scuff resistance achieves better and quicker break-in as well long-term wear resistance, and the coating allows the rings to be used with virtually any bore lining material, making them very versatile across engine applications.

- The top ring design overall has a tighter axial tolerance and tucked tips, aiding in ring seal and reducing wear at ring tips.

Second Ring – 1.2mm

- The second rings share the same carbon steel construction as the top ring, providing the same performance and durability benefits, while promoting less damage risk during installation. Carbon steel second rings provide better tension over common cast options.

- An optimized, Napier hook shape design provides the most efficient oil scraping during engine operation, which is crucial to keeping only the necessary amount of oil in the crosshatch of the cylinder. If too much oil is left, it can escape past the top ring and into the combustion chamber, decreasing power.

Oil Rings – 2.8mm

- Like the top rings, the oil rings in SP3 ring packages are also DLC coated, providing them with similar wear resistance and low-friction characteristics. Additionally, this coating allows the rings to be used with almost any bore lining material. As a package, these features benefit the oil rings with superior oil control capabilities.

All-in-all, SP3 DLC-coated pistons are a natural upgrade for performance engine builds of all shapes and sizes, from high-revving, naturally aspirated to boosted engine applications.

Pro Seal SP3 DLC-coated piston rings were developed and proven through extensive, in-house engine dyno testing. They were subjected to a 50-hour, 5-day dyno test in a turbo-charged, Mitsubishi 4G63 engine capable of 550+HP.

The test consisted of consecutive, increasing power pulls after a break-in period, after which everything was torn down and inspected to determine wear, performance, oil use, blow by, tension loss and more. The SP3 rings test was benchmarked against the same sized, non-DLC rings.

SP3 rings proved to reduce oil consumption, reduce wear both on the rings and in the ring grooves, and provide consistent power delivery throughout the tests.

One particularly awesome feature of Pro Seal’s SP3 rings is that they are supplied with a custom feeler gauge intended specifically for checking and setting ring end gap. Pro Seal knows end gap is critical to engine performance, so we want to equip you with the tools to get the job done right the first time!