V-Twin Power: Performance Forged Pistons for Harley-Davidson Milwaukee-8 Engines

The V-twin industry transformed when Harley-Davidson introduced its new Milwaukee Eight (M8) engine in 2016. As part of that transformation, JE Pistons is thrilled to announce the release of high-performance pistons for M8 engines. The JE Pistons team has been feverishly working away at exacting details and completing R&D processes, and now, these new slugs are ready to bring reliable performance to Harley Davidson’s arguably most exciting engine platform.

Harley-Davidson’s latest engine platform, the Milwaukee-8, created a lot of excitement and new potential power capabilities for the legendary V-twin brand.

What Engines Are These New Pistons Designed For?

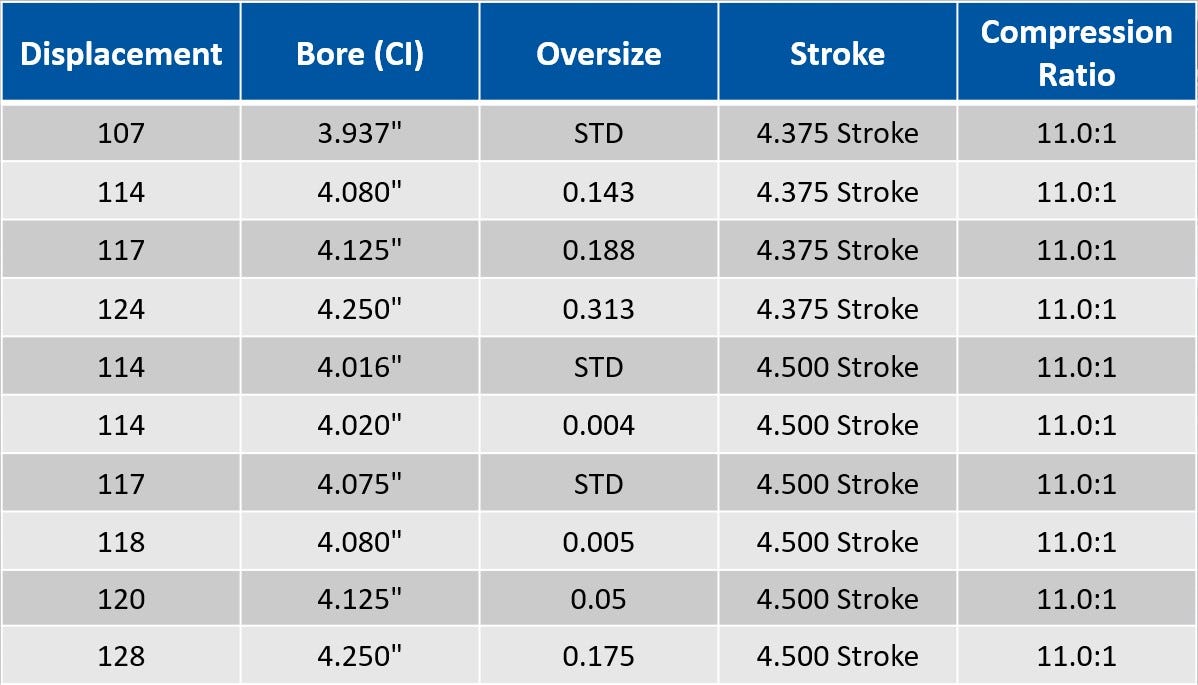

JE Pistons’ Milwaukee Eight pistons cover several displacement combinations. Whether you own a 107, 114, or 117 cubic inch engine, JE has you covered with multiple performance piston options. Each M8 JE piston package features a one-point increase in compression ratio over the stock design, resulting in a rise from 10.0:1 to 11.0:1, translating to a grip-tightening performance increase. Let’s take a closer look at the piston variants available for each engine family.

The table below outlines JE’s 10 different displacement combination piston offerings for the M8, all at an 11.0:1 compression ratio.

See all JE M8 piston part numbers and the complete product data sheet here!

Material Selection and Forging Process

Staying true to JE premium quality, 2618 aluminum alloy was selected for JE’s Milwaukee Eight pistons because it is an excellent forging material. The alloy offers superior tensile strength and provides the opportunity for weight savings throughout the design. It has a proven track record of unmatched performance and durability in the harshest of environments.

JE’s M8 pistons, like the rest of their offerings, are forged from 2618-T6 material for high tensile strength maintained through additional machining and weight saving. JE has been manufacturing pistons from 2618 for decades with unmatched results.

The piston’s forging is referred to as a “full-round forging,” which offers unmatched grain flow and excellent structural strength. The JE team utilizes a proprietary design technique known as “radiused side relief,” where unnecessary material is machined away from the base forging to reduce weight yet maintain strength. The culmination of these two techniques nets a very strong, light, and durable piston where further design features are incorporated to round out the design.

All M8 JE pistons are made with a full-round forging for superior strength qualities, but use a ‘radiused side relief’ design to reduce unnecessary weight.

Contact your favorite Harley parts dealer or supplier to check out JE M8 pistons

Key Design Features

JE Pistons’ M8 piston design offers enhanced features that contribute to the piston’s superiority over stock piston options. Let’s take a closer look at these unique features.

Increased compression ratio

JE’s M8 pistons feature a one-point increase in the engine’s compression ratio. This allows more compression of the mixture before combustion and additional expansion thereafter, resulting in more power.

All JE M8 offerings are designed with an increased, 11.0:1 compression ratio for an additional

edge in horsepower.

Accumulator grooves

The JE engineering team spent a significant amount of time working out the details of the piston’s accumulator groove geometry to ensure excellent ring performance. The accumulator groove gives unburned combustion gases that leak past the top ring a place to go. Without the accumulator groove, or with an improperly sized accumulator groove, ring flutter can occur. Ring flutter happens because the pressure build-up between the rings upsets the top ring and overall ring dynamics.

Accumulator groove design is a critical aspect to performance. It gives uncombusted gases that make it past the top ring a place to go in effort to reduce ring flutter and keep sealing at an optimal level.

Double broach pin oilers

One of the significant design features developed on this new piston is the double broach piston pin oilers. The Milwaukee Eight engine relies on splash lubrication to lubricate the joint between the piston pin bore and the piston pin, which makes this joint geometry especially important. JE Pistons’ double broached pin oiler geometry enhances lubrication and oil film distribution across the piston pin joint. The pin oiler ensures consistent and long-lasting performance from this critical area. Improved lubrication directly reduces joint temperatures, lessens friction and wear, and significantly boosts durability.

Double broach pin oilers drastically help increase top end component oiling, especially in splash oiling style systems, such as the M8 engine.

Low friction skirt coating

A dry film lubricant applied to the piston skirt helps reduce friction and improve performance. The enhanced fit between the piston and cylinder bore also reduces mechanical noise caused by the piston reciprocating up and down in its bore.

The M8 pistons’ skirt coating helps reduce friction and wear while also reducing operating noise.

Offset piston pin

A slightly offset piston pin bore is utilized, which improves the geometric relationship between the piston, crank, and connecting rod. The net of the improved geometry results in reduced piston rocking and thrust loading.

Packaging convenience

All of JE’s M8 pistons come conveniently packaged with everything you need to increase the performance of your engine. Each piston kit features two pistons and all the necessary hardware to upgrade both cylinders of your engine. Included in the kits with the pistons are piston rings, piston pins, and retaining clips.

Performance Gains

One of JE Pistons’ V-twin development partners, Axtell Sales, has achieved gains up to 40hp over stock by utilizing JE’s 4.125″ high-performance M8 pistons. Keep in mind that engines are a finely tuned combination of components, and these gains were achieved in combination with additional engine modifications. Gains for your specific engine and application can be expected, but exact numbers will be dependent on the overall engine build and state of tune achieved.