Boost-Ready: Forged Pistons for Ford’s EcoBoost Engine Line

JE Pistons offers a vast lineup of forged pistons for the various engine models under Ford’s EcoBoost platform. Learn about EcoBoost engine and piston technology and how specially designed forged pistons can optimize performance.

The popularity of Ford’s EcoBoost family is validated by the growing number of enthusiasts who are rebuilding their engines with upgraded parts, taking the versatile platform to the next level in street and racing performance.

First introduced for the 2010 model year, millions of 4- and 6-cylinder EcoBoost engines have since been produced for a wide range of vehicles—including a hyper-performance model that boasts more than 600 horsepower. The EcoBoost line was developed out of an industry trend to downsize engines and introduce direct injection (DI) to help meet federal fuel-economy targets. The second part of the strategy uses turbochargers and boost when needed for passing, towing and other demanding driving functions.

When rebuilding the EcoBoost, performance enthusiasts have access to a full line of power upgrades across the engine architecture, including the rotating assembly where JE Pistons offers dedicated FSR forgings for most of the engines. Currently the JE EcoBoost lineup includes the Gen I & II 3.5L V6 and the 1.6L, 2.0L and 2.3L four-cylinder engines.

“We’re also getting requests for the 2.7-liter V6,” says Nick DiBlasi, director of product development at JE Pistons. “The EcoBoost is a good-performing engine, and a lot of people are modifying it in different versions. We have a standard FSR series and an Ultra series that will cater to each type of customer.”

Get Complete EcoBoost Piston Part Numbers & Data Here

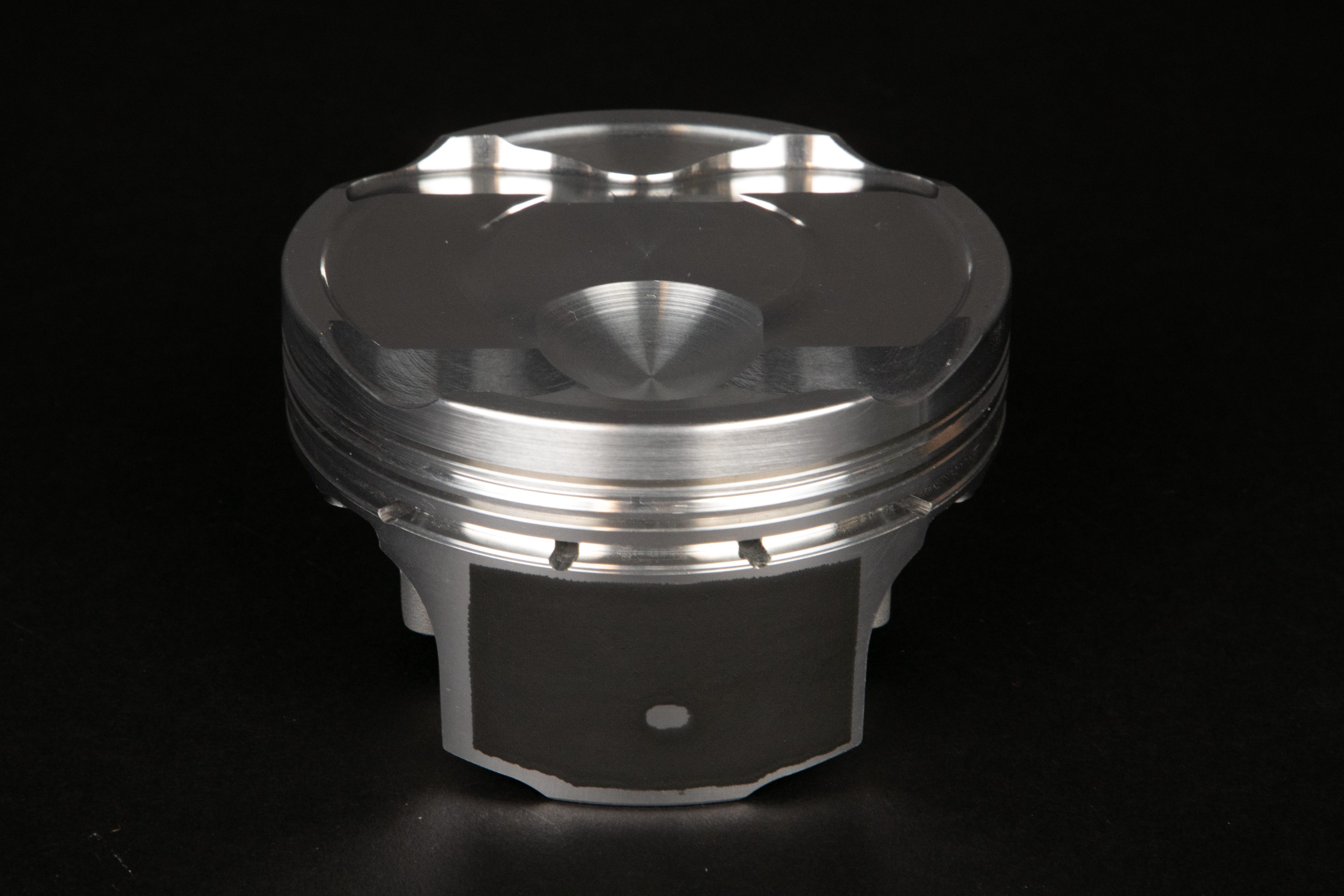

The EcoBoost FSR (forged side relief) pistons are forged from 2618 aluminum alloy and come with 5115 steel wrist pins. They’re available in standard or a variety of overbore sizes, and different compression ratios may also be offered. Off the shelf, the standard FSR has a skirt coating and is good for 600 to 800 horsepower with upgraded wrist pins.

JE’s Forged Side Relief (FSR) design optimizes strength-to-weight characteristics.

FSR style EcoBoost pistons from JE are standard equipped with skirt coating and are good for 600 to 800 horsepower with upgraded wrist pins.

The Ultra series is initially available only for the 3.5-liter V6 but may be expanded to other applications, including the 2.3L in the near future. Also forged from 2618 alloy, the Ultra series comes with an upgraded 9310 wrist pin. In addition, the skirts feature a friction-reducing moly coating while the crown has a ceramic thermal coating.

“We have several customers making 1,500 to 1,800 horsepower on either a custom or the Ultra series off the shelf,” notes DiBlasi. “People are putting them into off-road applications and a lot of drag-race swaps, so we’re seeing a lot of traction on the six-cylinder engines, like in the Raptor.”

The key feature on the Ultra series is the manufacturing process that enables JE to align the grain in the forging, which produces a piston that is about 20 percent stronger than a standard forging.

“It’s a more robust design and you need that when you’re limited in weight and size,” explains DiBlasi. “We have a different manufacturing process that enables us to align all the grain, so it’s a stronger part without the added weight. If you make it too heavy, then you beat the bearings out of the engine at some point. So, we improve the technology of the forging itself.”

The key to the Ultra Series’ increased strength is JE’s proprietary Aligned Grain Flow technology.

“We have a different manufacturing process that enables us to align all the grain, so it’s a stronger part without the added weight.”

The Ultra series also features lateral gas ports for improved ring seal. The ring package is 1.0mm, 1.2mm and 2.8mm and is more strategically placed on the piston than the factory model.

“We try to move the rings down as much as possible in a performance part,” explains DiBlasi. “The further you can move the rings down, the more heat you get off the rings. Then we fit a thicker ring pack for big boost. If it was a naturally aspirated application, it would be a different story, but these are direct injection with turbochargers.”

With direct injection and a high-cylinder-pressure environment, the lower ring location and larger ring pack will help improve oil control and consumption. JE also address ring tension when setting up its ring package.

“There’s different design to the oil rings that we use. It’s a fine line that if you add too much tension, you’re actually creating drag. So, we’re trying to balance having better oil control without having a ton of drag,” adds DiBlasi.

For the Ultra line in the Gen I & II 3.5L engines, JE offers a 10.0:1 compression ratio with standard, .015- and .025-inch overbore options. The crowns are machined to accept oversize valves and accommodate increased valve lifts. The crowns are also designed to imitate the factory profile.

“We copied the crown almost exactly. If you don’t, the spray pattern is going to be completely off,” says DiBlasi. “You could easily spray fuel right on the cylinder wall, wash off all the oil and cause damage. So it’s really important that we keep the height and position of the DI bowl because the injector is fixed. To adjust compression, we’ll deepen the pocket. We can move everything else around that’s less critical.”

JE offers compression-ratio options for the 3.5L FSR series, which is quite robust and features the same 1.0, 1.2 and 2.8 mm ring package. For the Gen I, compression ratio options include 9.0:1 and 10.0:1 (with 56cc combustion chambers) in standard, .025- and .050-inch overbore. For the Gen II 3.5L, there are 10.0:1 and 10.5:1 compression ratio (with 43cc combustion chamber) in standard, .013-, .025- and .050-inch overbore. Compression ratio and bore options also vary across the standard FSR four-cylinder EcoBoost lineup.

“It’s still a performance piston because it’s forged from 2618 alloy,” reminds DiBlasi. “The crown, skirts and ring lands are larger. Even the standard wrist pin is stronger than the factory pin. Our basic piston is substantially stronger than the OEM.”

Skirt design is an important element in the overall performance from a piston upgrade, since the skirt is necessary to stabilize the piston. If the piston “rocks” too much inside the cylinder, the piston can become damaged and there will be significant loss of ring seal. Conventional pistons are a full-round design, meaning the skirt matches the cylinder bore. That design made sense in the early years of engine development, especially for cast pistons that needed strength and durability.

Engineers have since discovered that full-skirt contact with the cylinder is detrimental to piston performance. The FSR design strategy reduces the skirt-width area on each side of the piston that is parallel to the wrist pin, thereby eliminating the skirts that normally would support the pin bosses. Now the pin bosses can be positioned closer together since they’re not part of the skirts. This action not only reduces weight by shortening the wrist pin, the overall skirt design now minimizes the contact area between the piston and cylinder wall, thereby reducing friction.

On some FSR pistons, the skirts are symmetrical or equally sized on each side. The other FSR pistons have asymmetrical skirts—meaning the thrust side of the piston has a larger skirt area than the non-thrust side. For the JE EcoBoost line, the skirt design varies according to the OEM strategy.

“It depends on the factory forging; also, what the crankshaft counterweights look like and if there are oil squirters (for the bottom side of the pistons),” explains DiBlasi. “If you have an oil squirter, as the piston comes down, it can intersect with the skirt. So we have to look at where the oil squirter is at bottom dead center and making sure you’re spraying the bottom of the piston crown and not the skirt.”

Whether it’s a performance upgrade or an all-out race build, the EcoBoost engines will benefit from a JE Piston product. The lineup offers numerous bore sizes and compression-ratio options, and the Ultra series is designed for extreme duty applications. More important, the JE EcoBoost line is a definite performance step up from the factory replacements.

“I think it’s peace of mind,” sums up DiBlasi. “Every new engine in the last 20 years was designed for just a small factor of safety over the factory horsepower rating it came with. If you want to make any amount of power, an aftermarket piston is the way to go because it’s a bulletproof design. You can make all the power you want. You can always detune it to the factory or turn up the boost on weekend and still be reliable. It’s truly peace of mind for a low cost.”